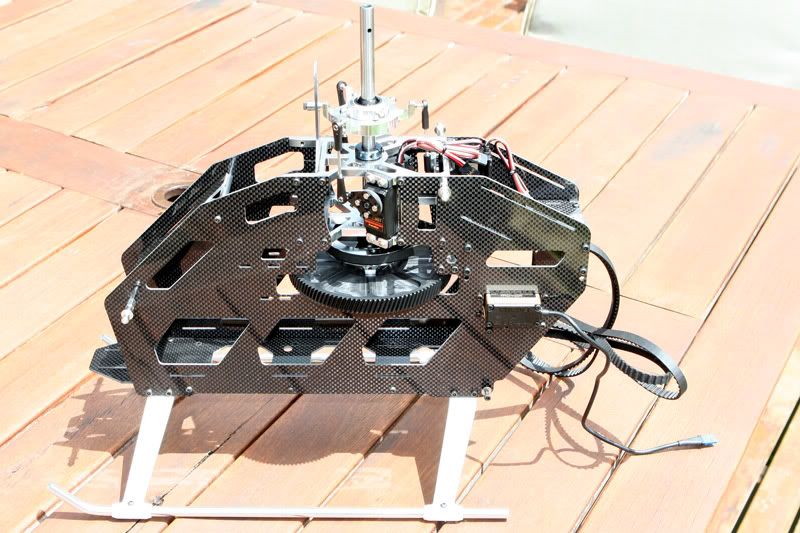

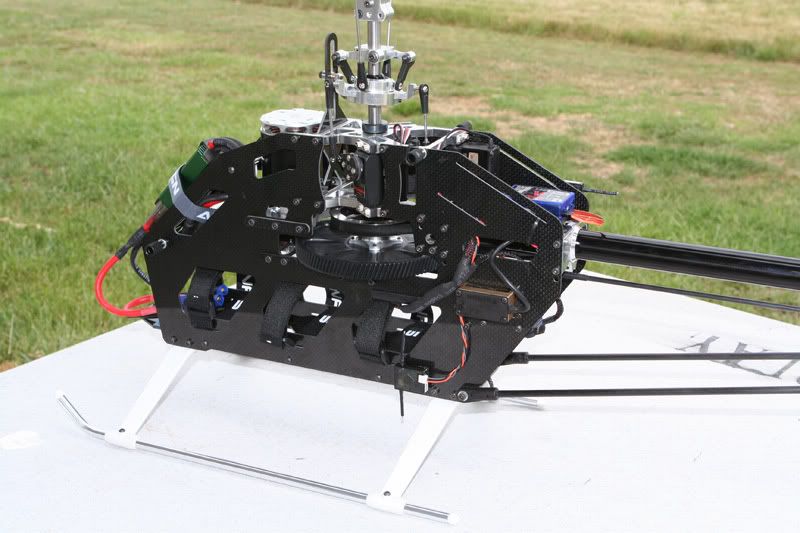

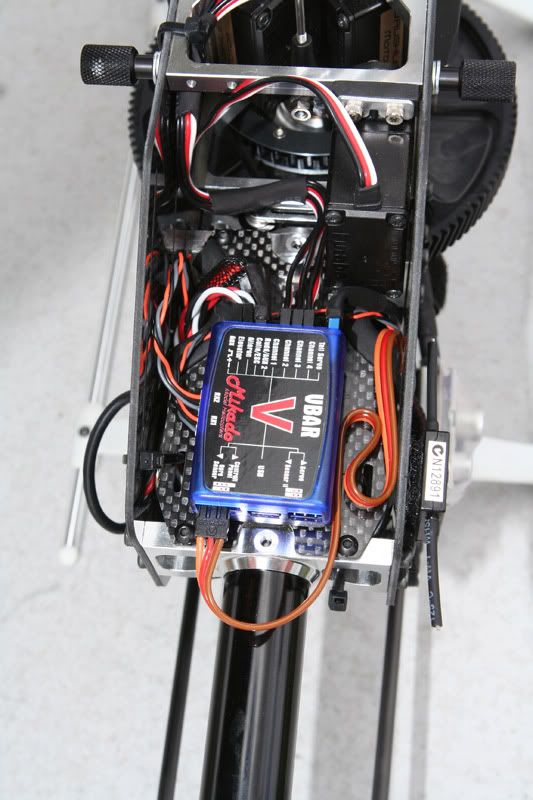

Thought I'd post a few E7 build shots and notes (thanks for some of the tips from others on this forum) on the build. Note this is not a full-on build thread...

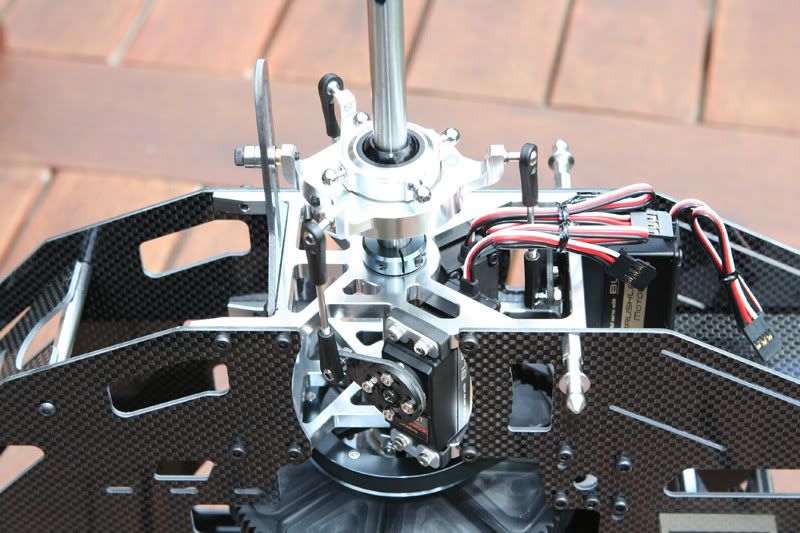

* The quality of the kit is awesome

* Clean out the one-way and oil it until it spins freely. I originally greased mine and it felt notchy until I was advised by those in the know to clean it out and use oil. Much better now

* The screws that attach the auto hub to the main gear already had threadlock, as did the screws making up the belit drive in the transmission. I have pulled all other pre-assembled parts apart and applied threadlock

* When attaching parts to the main frame, note that the screws attaching the lower bearing block and belt idler are M3x8. All the others are M3x6

* My one-way was reversed so I had to flip my main gear and insert the auto hub from the other side as advised on the Synergy support forum - easy fix

* There is good access to the tail servo to install the servo arm later in the build

* The M3x16 socket head is for the boom supports

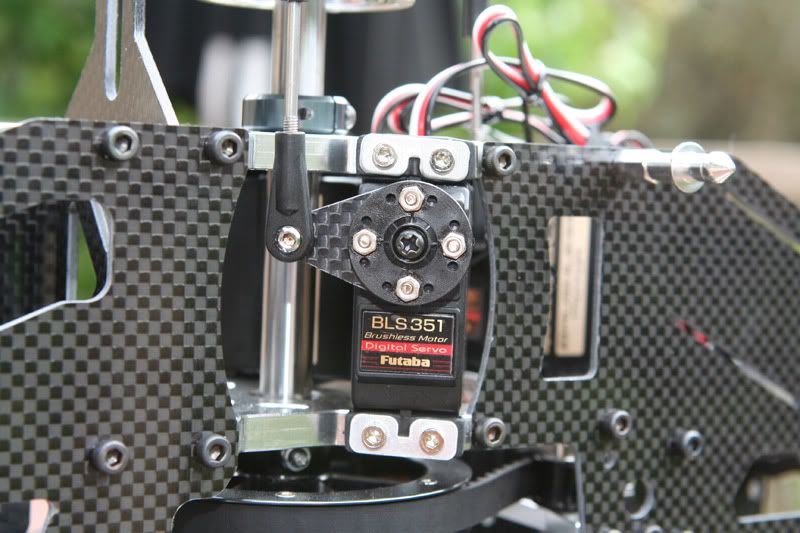

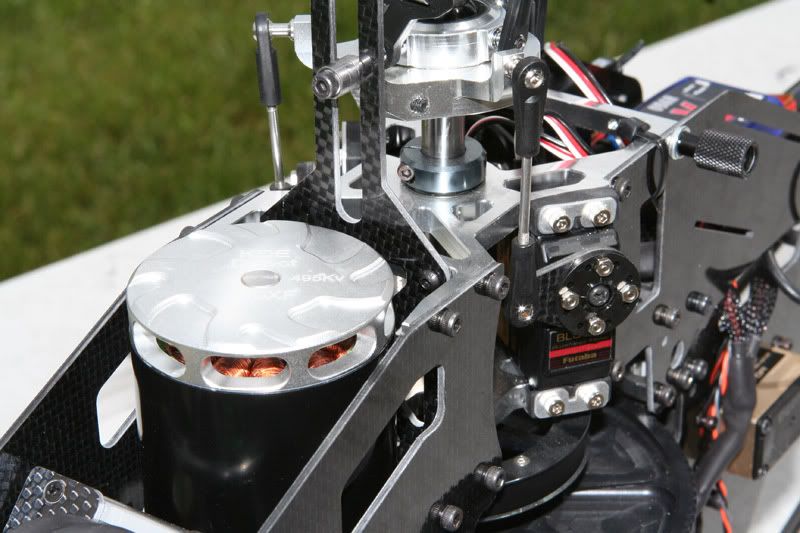

* Plug the servos into a receiver before mounting to find the best horn position

* There is a smaller and larger diamater hole in the ball links so make sure they go on the correct way

* The thrust bearings in my kit were assembled incorrectly, so definitely redo the head and grease the thrust bearings. They are a very tight fit so heat them first

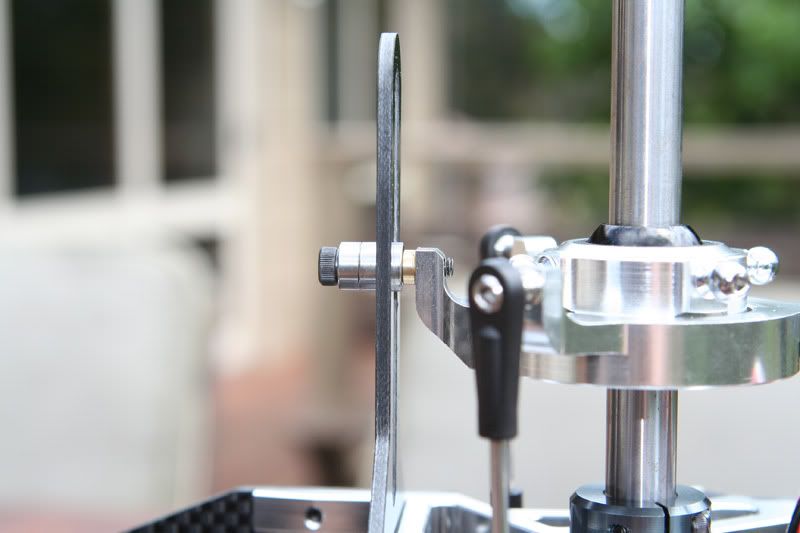

* A good tip for ensuring no phasing is to flip the washout link up and centre it on the slit in the head block (thanks Churchy)

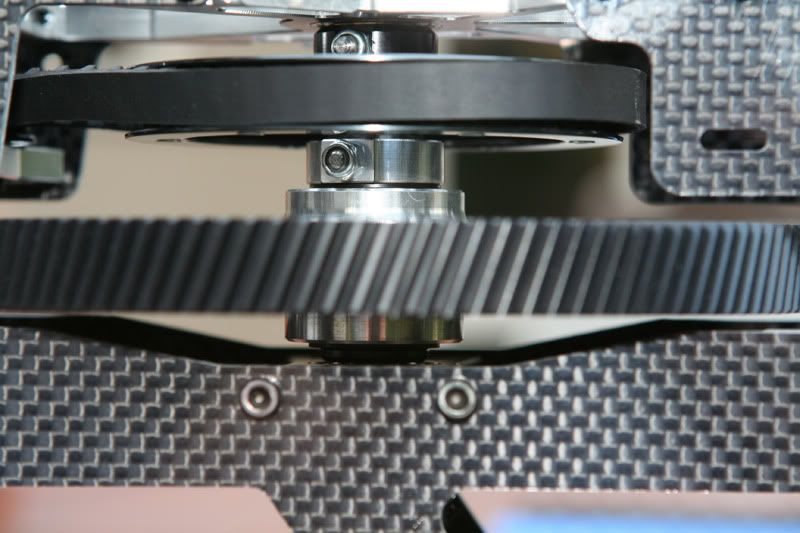

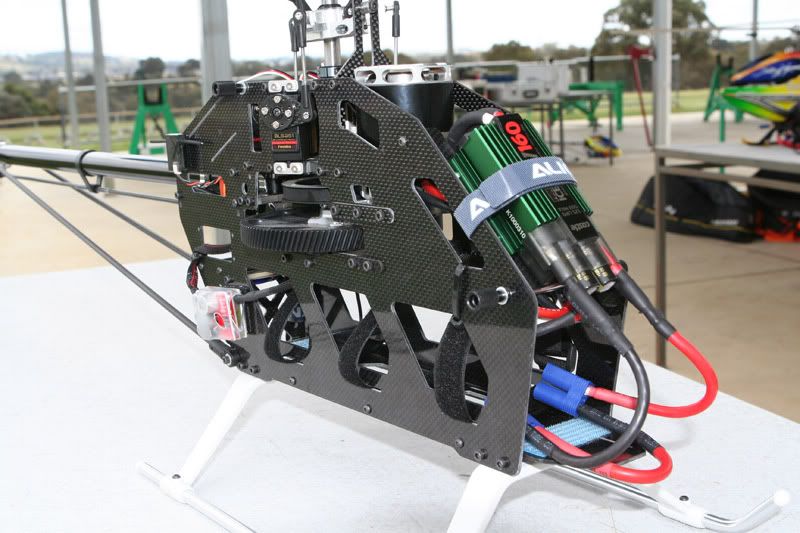

* Set the motor pinion height before attaching the ESC tray. It is hard to access otherwise

* If you plan on running wires inside the frames, dremmel out some of the radio plate tray sides to allow wires to travel from the bottom to the top

* Be careful when CAing the boom support ends to the boom support. They stick quickly so you do not want them twisted

* According to Matt B, you want to install the tail ouput shaft with at least 4 or 5 mm sticking out of the tail box assembley

* When installing the tail push rod, first put the two ball links on a rod and screw them down. Then unscrew them and install. This loosens them up and makes it easier to make adjustments without breaking the glue bond

* Also on the tail rod, glue in one end, let it set and attach it to the tail servo and then glue the tail end during the vbar setup. This way you can glue the tail end in the exact location with no need to make any link adjustments

Thats it for now