Synergy E5 (600size) MD500 G-JIVE Scale Build Project

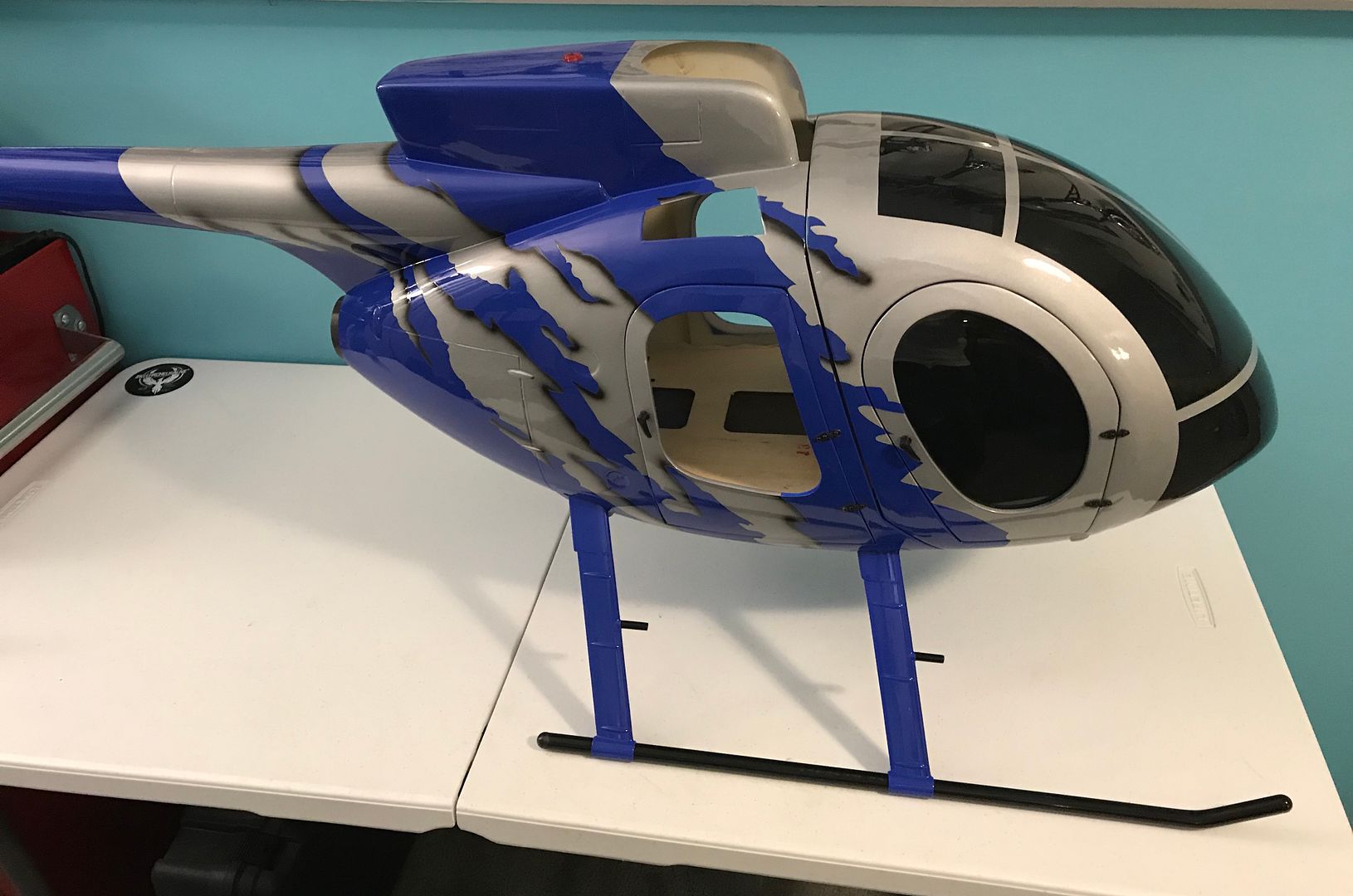

OPENING THE BOX

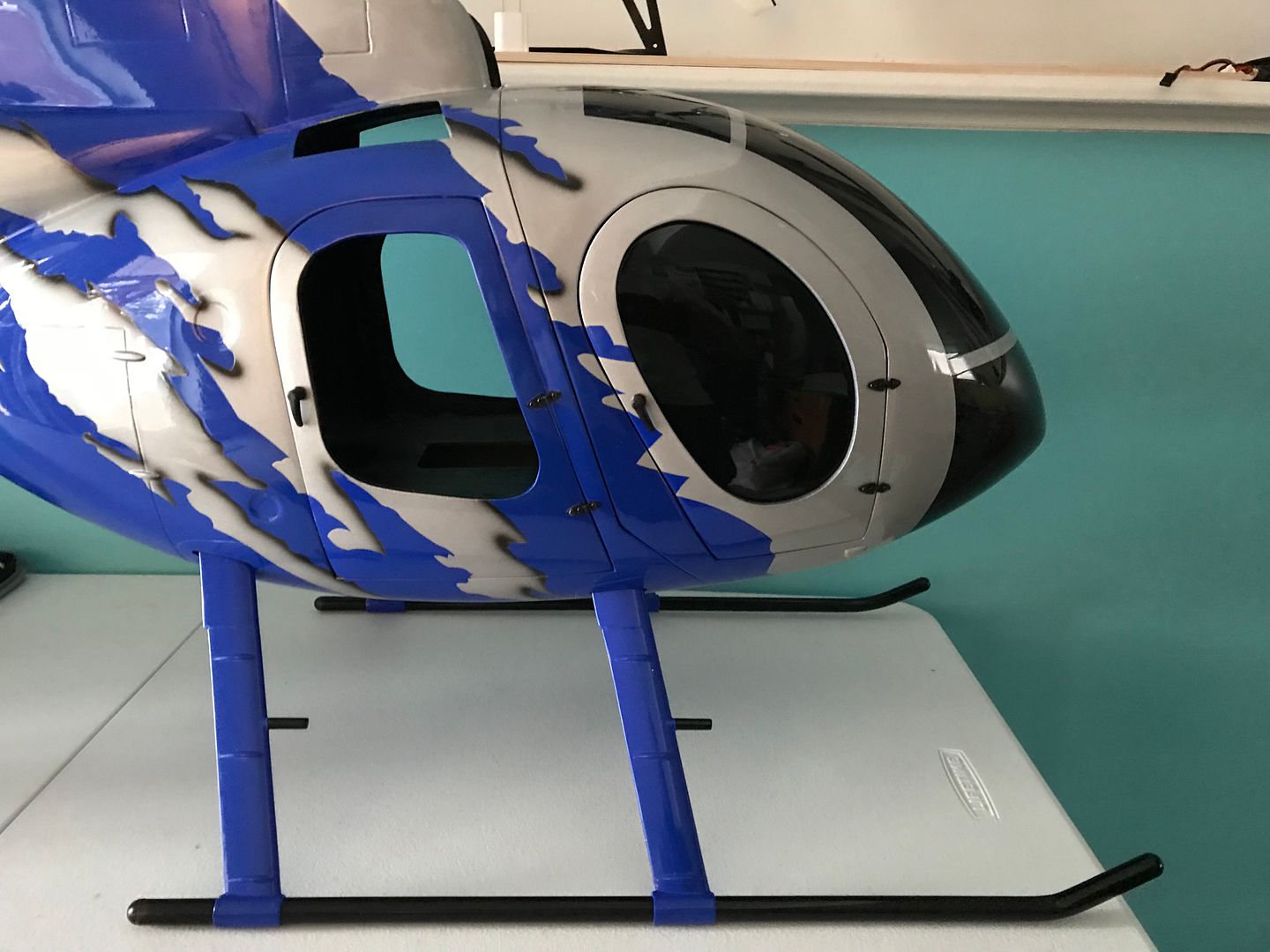

Opening the box I found everything well packed in plastic bubble wrap divided by cardboard to ensure a secure fit during the shipping process. Upon unwrapping the fuselage you are greeted by the most vibrant bright airbrushed colors. The fiberglass was smooth and flawless with no cracks or blemishes. I choose the blue G-Jive paint scheme again as I have done this scheme in both red and blue in past 450 size MD500 builds and really enjoyed it. With all the parts laid out it was time to start the Synergy E5 scale build project.

LET THE BUILD BEGIN

Mechanics / Electronics Chosen For The Scale Build:

- Helicopter: Synergy E5

- Cyclic Servos: MKS HBL665

- Tail Servo: MKS HBL669

- Gyro: Mikado NEO

- Motor: Scorpion 4025-1100KV

- ESC: Castle Talon HV120

- Battery: Pulse 5000mAh 45C

- Blades: RAIL 556mm/96mm

Tools / Items Used For My Build:

- 5 Min Epoxy

- Super Glue

- Black Testors Spray Paint

- 2.5mm Screws, Washers and Lock Nuts

- Dremel

- Hot Glue Gun

- Canopy Reemer

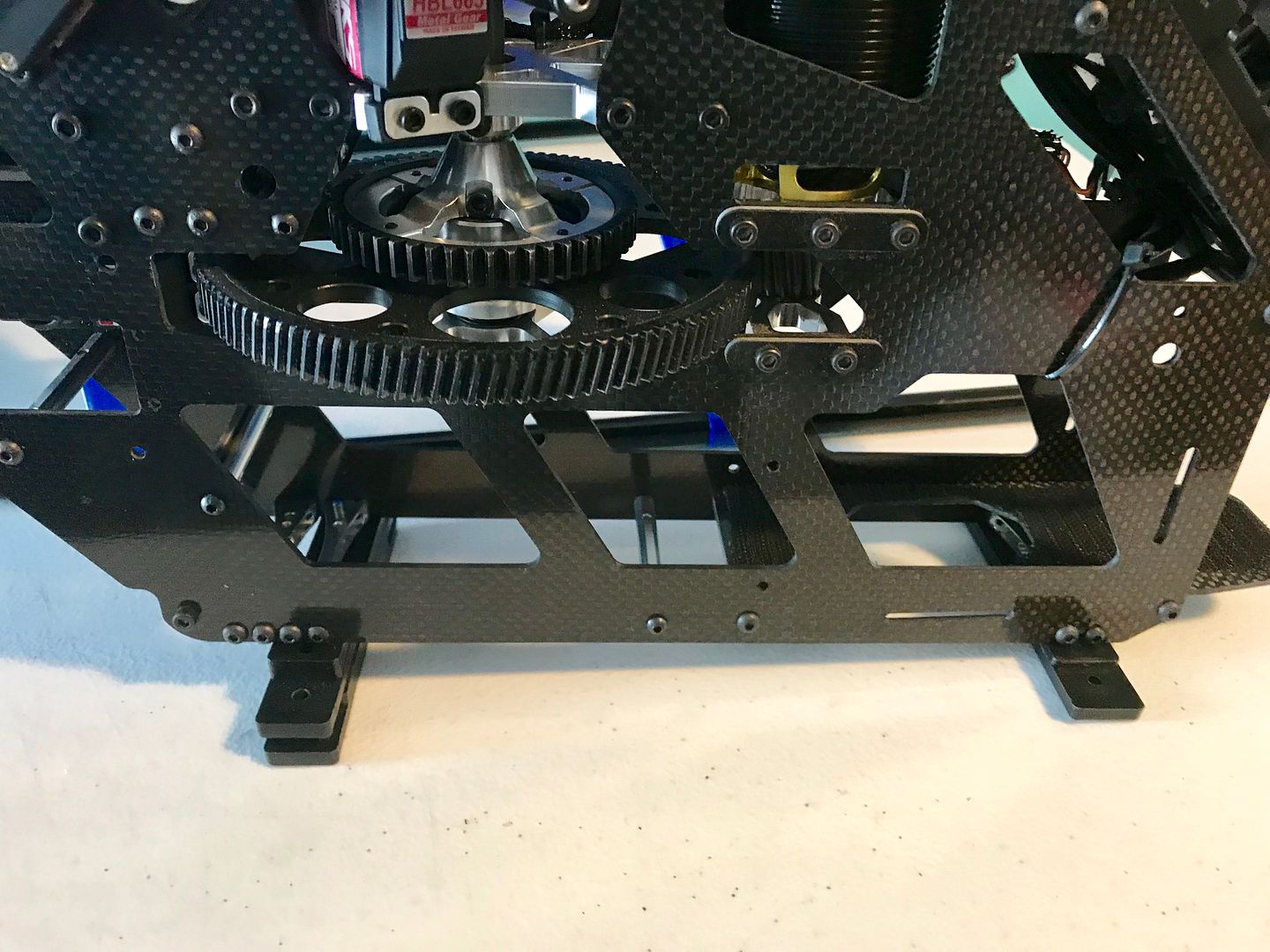

Step 1: PREPPING THE MECHANICS

Once you have your Synergy E5 built and have test flown it a few times it is time to prep the helicopter to fit into the scale fuselage. The parts you will no longer need anymore include the main skids, boom supports, vertical fin and canopy. Once you removed those parts you will need to temporally remove the rear torque tube tail case. I also recommend removing the main blades so they are not in your way during the installation portion of the build. Once everything is removed you are now ready to start your scale build journey.

Step 2: MOUNTING THE LANDING SKIDS

The first step of the build consists of installing the skid risers into the body of the fuselage. You want to test fit the skids into the wood plate inside the fuselage and insert the pipes before adding epoxy. Once test fitting has been done and everything looks good add some 5-30min epoxy on the skids, inside the frame on the floor where the skids come through the fuselage and where they seat into the wood deck framing. Once everything is true and straight put a battery inside to add some weight so that the glue can set up ensuring everything dries straight and even during the drying process. Once the glue has dried you can move into fitting the mechanics.

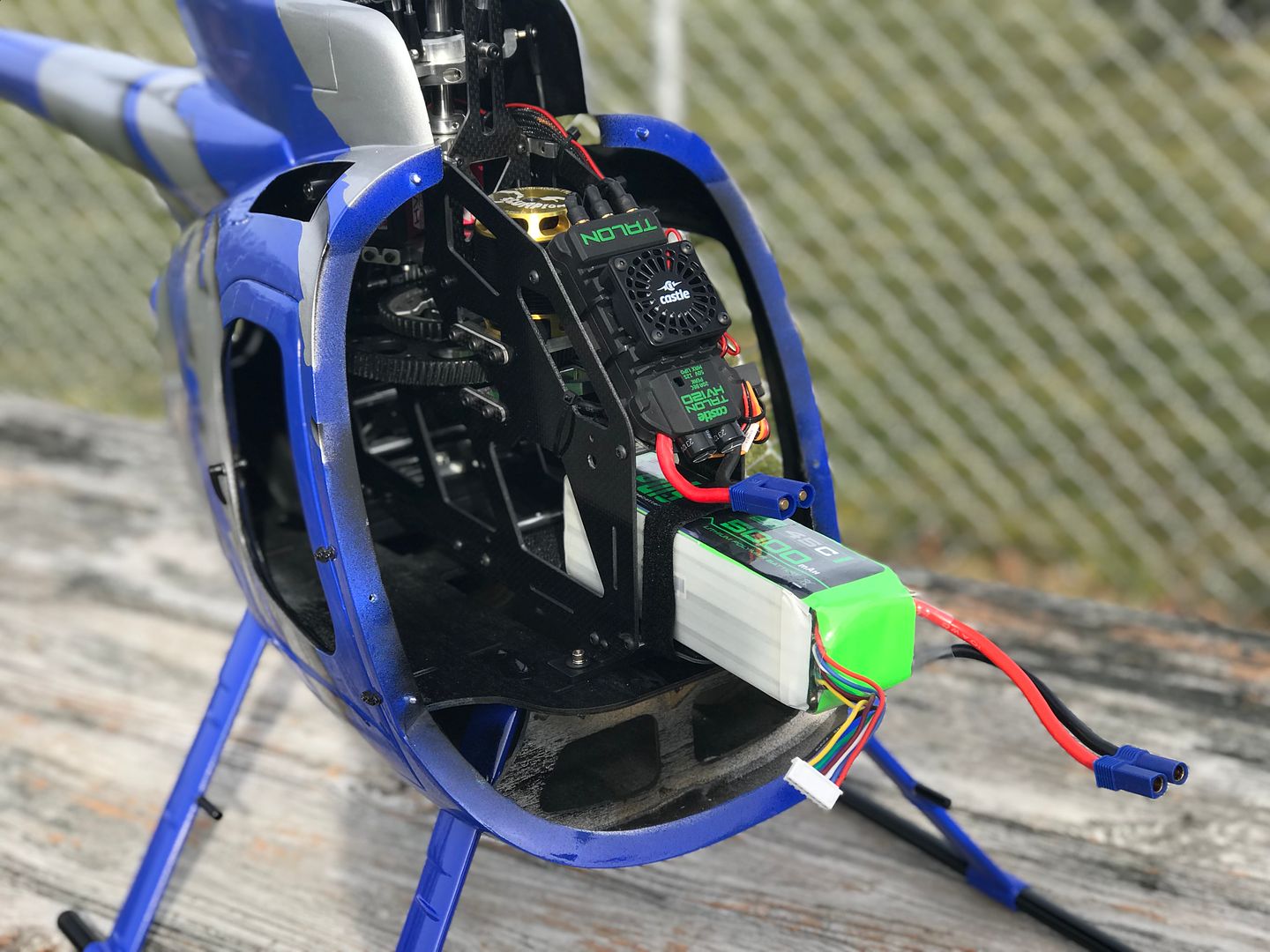

Step 3: FITTING THE MECHANICS

Time to fit the mechanics into the MD500 fuselage. Unfortunately the E5 only slid about 6” into the fuselage before the elevator servo hit the inside of the fuselage side. My first building decision was upon me and took some thinking. I wasn’t about to cut a channel in the side of the fuselage to fit the E5 nor was I going to give up on the build project. First thing I did was mark what the servo was hitting and dremel all the wood former down to the fiberglass fuselage where the servo was hitting. This allowed another inch to slide the E5 into the fuselage but the elevator servo still hit the side of the fuselage. To resolve this issue I decided to shim the elevator servo. I used servo spacers and shimmed the elevator servo into the frame about a 1/4 inch. To keep the elevator servo geometry correct I flipped the servo ball around to the back of the horn to regain perfect servo geometry. With this modification out of the way the E5 slid all the way into the fuselage with about an 1/8th clearance between the elevator servo case and fuselage wall. The next task was to achieve the proper height of the E5 with the included plastic riser blocks so that the tail boom centered straight down the fuselage. I doubled up the two thicker riser blocks in the rear and used the thinner riser block in the front. You need to mark where the tail pushrod will poke through the fuselage and Dremel a big enough hole for the tail pushrod to move free without any binding on the control rod. There are holes in the middle rear of the fuselage deck with blind nuts epoxied on the under side of the deck. To make sure the riser blocks on the E5 lined up with the holes in the fuselage I removed the rear bottom battery tray and drilled new holes to relocate the rear landing skid mount on the E5 frame that hold the riser blocks. It is very important that the mechanics are centered inside the fuselage, you have equal spacing on the left and right side of the frame and the tail boom is centered down the fuselage. With the airframe now fitting perfect I secured the riser blocks to the E5 with loctite and slid the E5 back into the fuselage sliding the tail pushrod through the hole I previously cut out. If you want to paint the inside of the fuselage black like I did to hide the mechanics do that before reinstalling the E5 back into the fuselage. I used 2.5mm screws with lock washers and tightened down the rear riser blocks to the deck. Next I drilled out the holes through the front riser blocks into the wooden deck. I could not get to the underside of the screws so I used a canopy reemer tool and made two small holes on the bottom of the fuselage so that I could insert my nut driver and installed the locknuts onto the 2.5mm bolts. With the E5 securely mounted into the fuselage I moved on the tail section of the build.

Servo hitting the inside wall and wooden frame spacer

*Carefully* dremel away access wood does to the fiberglass

Shim elevator servo into frame

Perfect Fit

Frame riser blocks

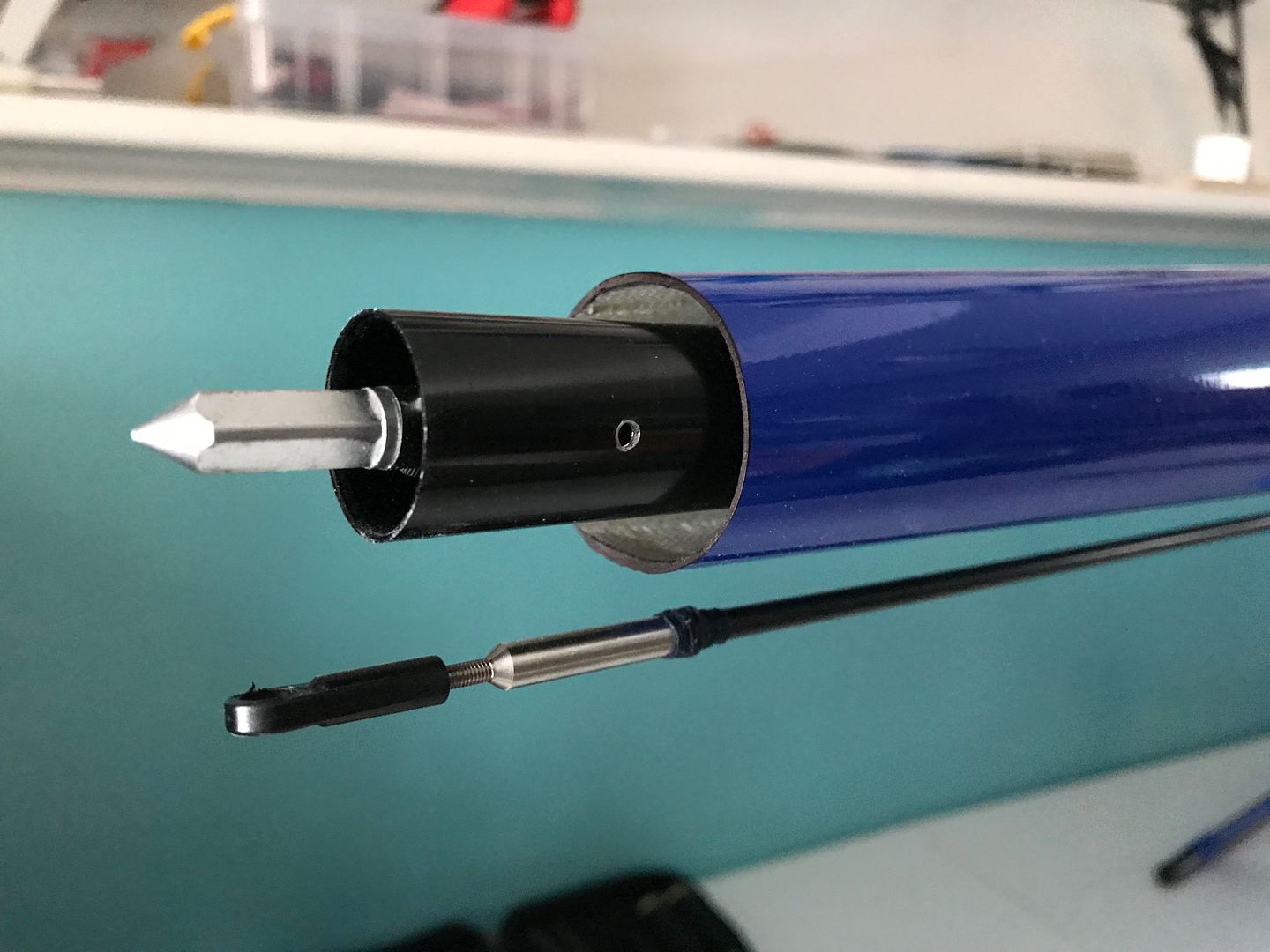

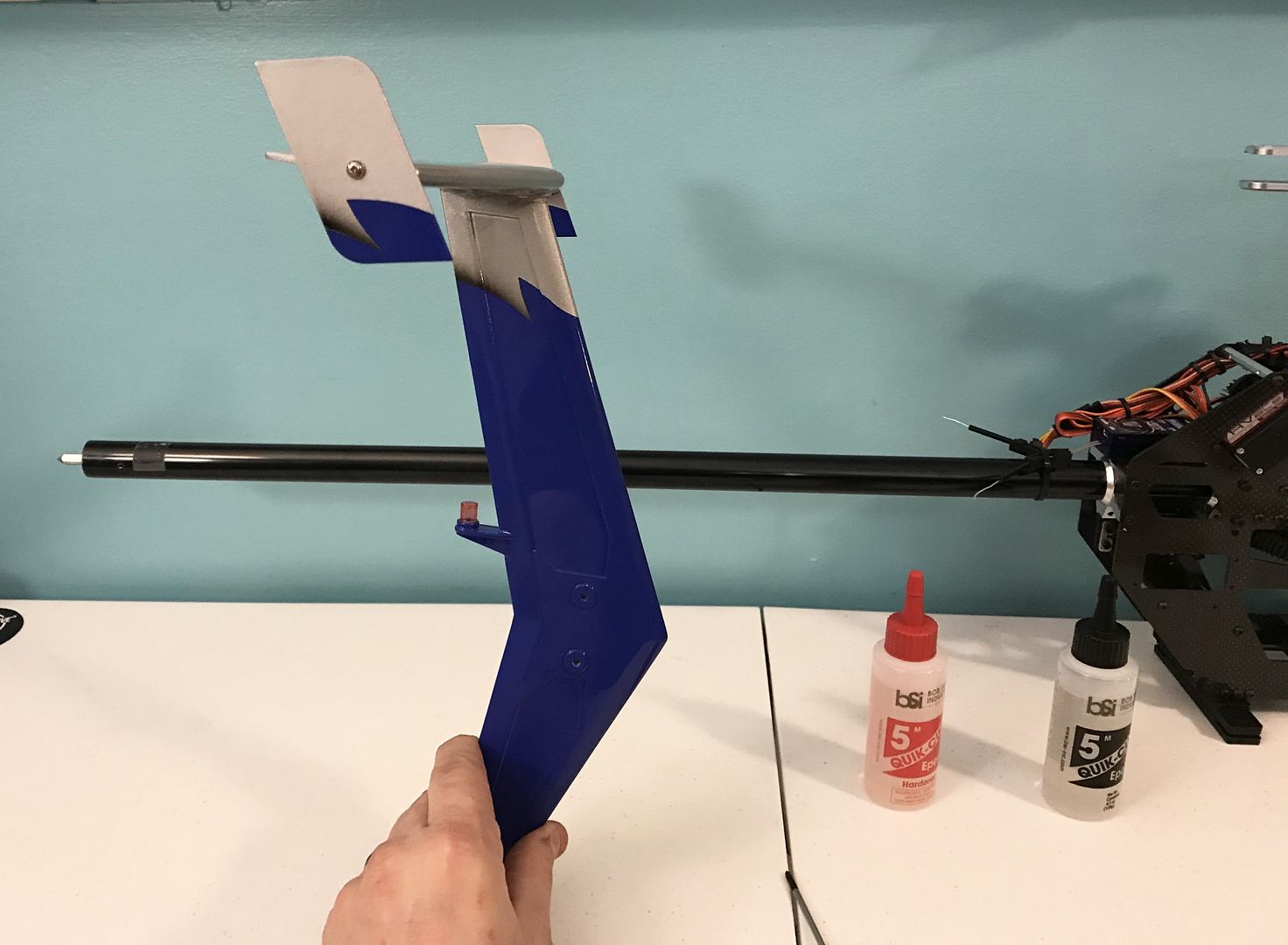

Step 4: INSTALLING THE REAR TAIL CASE AND SCALE VERTICAL SCALE FIN

With the E5 installed into the fuselage the fuselage was longer than the end of the E5’s boom. After careful measurements of how much fuselage I needed to cut off I hit it with the dremel and removed about 1 1/2” of fiberglass. I carefully sanded the tip of the fuselage and ran around the back edge with a black marker to help conceal the cut off tip. Make sure you install the foam tail boom guide before installing the tail case. It just slides over the boom and keeps the tail boom straight in the fuselage. Next I slid the E5 tail case back onto the tail boom, installed the pinning screw into the boom and attached the tail pushrod link. To assemble the scale tail fin use epoxy to glue the vertical and horizontal fin assembly together and use the small screws provided to add the small vertical side fins. The mounting holes in the side of the vertical fin are meant to fit an Align Trex 600 tail case and did not match up with the Synegy’s tail case mounting holes. I used the bottom hole as my guard and drilled a new upper mounting hole. On the Synergy E5 the two rear screws don’t just hold on the vertical fin, they secure the rear tail case onto the tail boom. You will need longer 2.5mm screws and washers to mount the scale fin assembly to the tail case. Lastly I installed the main rotor blades and clicked the front canopy in place to complete the scale E5 build. The next step is purely visual and up to the builder as too how far they want to go with the scale details.

Measure and cut off access fuselage boom to allow tail case to install

Step 5: FINAL DETAILS - WINDOWS / DECALS / PAINT / NAVIGATION LIGHTS

Next I decided what windows I wanted to paint and install. Before cutting out the windows I painted the inside of all the windows and the inside of the canopy nose. You do not have to take out the mechanics to install the rear side windows as the doors open and can be removed. I choose to leave my rear side and top windows out to let the E5 breath better on hot summer days. The E5 mechanics and main gear are black along with the complete inside being painted black it blends the mechanics pretty well inside the fuselage. I like to use hot glue to install the windows because it is not permanent and if needed, you can just peel the windows right out. I decided to tint my windows because I did not want to see the E5’s mechanics inside the fuselage nor could a scale cockpit fit inside with my E5’s layout. Depending on the model helicopter airframe used, you can get a scale MD500 cockpit and pilot for this fuselage. Once all the paint had dried and the side windows were installed I lined up the front canopy nose and let the magnetics click the nose onto the 4 canopy posts. I then finished the build off by installing a full navigation lighting system I also picked up from MotionRC.

Windows installed / Ready for interior paint

Step 6: FLY!

It was time for the first real flight with the new fuselage installed around my Synergy E5. To achieve the perfect CG without adding any extra nose weight I slid the 5000mAh 6s pack about 2” forward off the front of the battery tray. As it spooled up the excitement of a new scale build raced through my body. Around half stick she was light on the skids and lifted off into the air. Other than the new weight of the fuselage my E5 had a small tail wag. The MD500 sounded and flew amazing. It flies different and heavier than the E5 by itself but it still had quick response and performed very well in its new fuselage. I ended up lowering all my rates from 120 to 100 in the NEO and increased my expo by 10 to give the model a softer less aggressive flying style. If you fly it slow and smooth it looks like the real MD500 buzzing around the sky. Once the winter weather had cleared up a little I was able to take the MD500 to the field for some full flights.

CONCLUSION

It felt great and rewarding to get my Synergy E5 into a scale helicopter fuselage and to be flying a scale machine again. It has been over 3 years since I had built and flown a scale helicopter and I’ve missed having a scale machine in my hanger. The build was quite enjoyable and fairly quick considering the brain storming and modifications I had to make to fit the E5 into the fuselage. This fuselage kit is a great build for an amateur looking to get into a first scale helicopter. The MD500 is a very versatile fuselage allowing many different brand helicopters to be used for its mechanics. I was impressed with the overall quality of the fuselage kit and had no problems with any of the parts fitting together. If you are looking to try your first scale heli build check out the guys at MotionRC to see their line of scale helicopter fuselages and accessories. They have everything you will need to get your scale heli into the air.

See you guys at the field!

-Chris

Videos

Unboxing, Build and Maiden Flight Video

https://youtu.be/JN9nNz3aiOkMaiden Flight and Overview Video

https://youtu.be/jqlCJVfRg8w